How one UP senior is getting first hand biomedical experience creating a prosthetic

With the energy students spend juggling school, extracurriculars and jobs, many will dedicate their free time to scrolling TikTok, exploring Portland or pursuing passion projects.

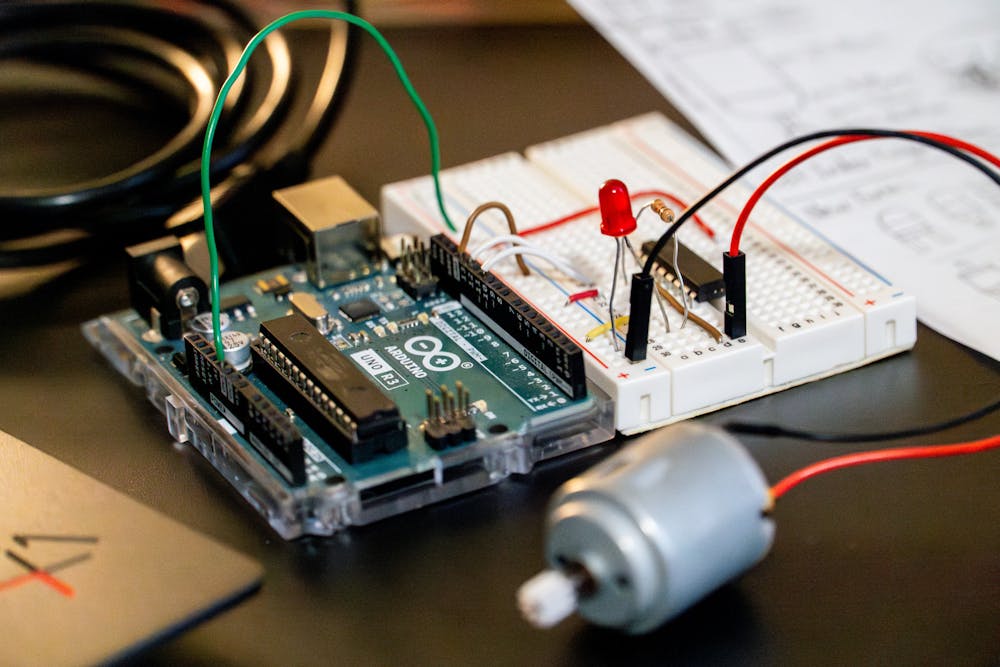

Senior electrical engineering major Sam Catelani is no exception. Since January 2024, Catelani has spent school breaks on his passion project: a neural-powered prosthetic hand.

“Essentially [the concept] is like a baseball cap that you wear connecting to your prosthetic hand,” Catelani said. “That is reading the commands that your brain is sending out and then shooting it into the hand so that it can move and function just like a normal one would.”

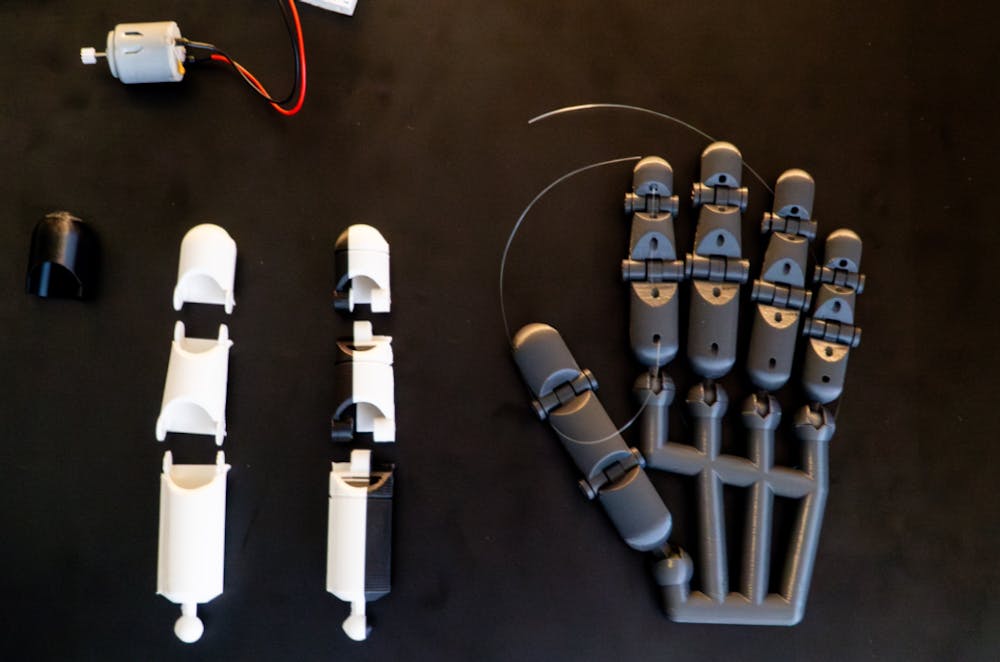

Using the Donald’s Garage Maker Space’s resources, Catelani’s project is an over year-long journey spent drawing, virtually designing and 3D printing a prosthetic hand. The hand is created by the Maker Space’s 3D printer using acrylonitrile butadiene styrene (ABS), a thermoplastic, and a fishing line for the hand’s tendons.